Report Overview

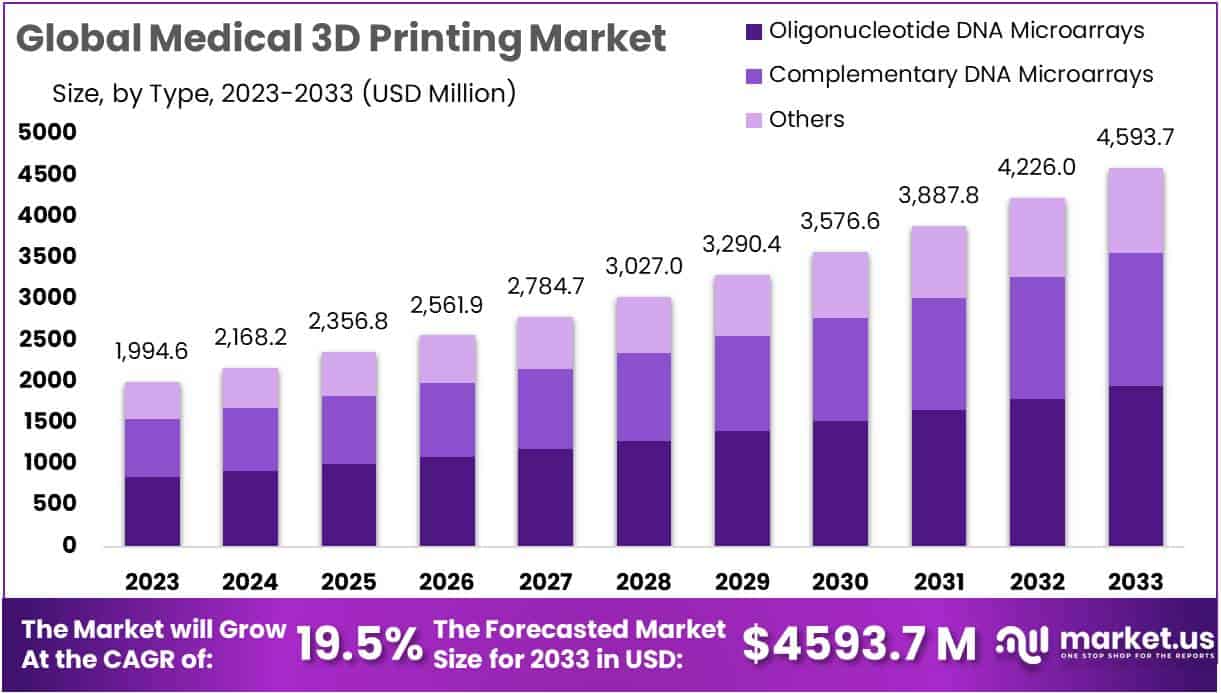

The Global Medical 3D Printing Market size is expected to be worth around USD 4593.7 Million by 2033, from USD 1994.6 Million in 2023, growing at a CAGR of 19.5% during the forecast period from 2024 to 2033.

Get a sample copy of the report to know more https://market.us/report/medical-3d-printing-market/request-sample/

Key Market Segments

Component

- System

- Materials

- Services

Technology

- Droplet Deposition

- Photopolymerization

- Laser Beam Melting

- Electronic Beam Melting

- Laminated Object Manufacturing

- Others

Application

- External Wearable Devices

- Clinical Study Devices

- Implants

- Tissue Engineering

End-Users

- Hospitals

- Ambulatory Surgical Centres

- Academic Institutions

- CROs

- Others

Key Regions

- North America (The US, Canada, Mexico)

- Western Europe (Germany, France, The UK, Spain, Italy, Portugal, Ireland, Austria, Switzerland, Benelux, Nordic, Rest of Western Europe)

- Eastern Europe (Russia, Poland, The Czech Republic, Greece, Rest of Eastern Europe)

- APAC (China, Japan, South Korea, India, Australia & New Zealand, Indonesia, Malaysia, Philippines, Singapore, Thailand, Vietnam, Rest of APAC)

- Latin America (Brazil, Colombia, Chile, Argentina, Costa Rica, Rest of Latin America)

- Middle East & Africa (Algeria, Egypt, Israel, Kuwait, Nigeria, Saudi Arabia, South Africa, Turkey, United Arab Emirates, Rest of MEA)

Market Key Players

- Formlabs Inc.

- General Electric

- 3D Systems Corporation

- Exone Company

- Materialise NV

- Oxferd Performance Materials Inc.

- SLM Solutions Group AG

- Organovo Holdings, Inc.

- Proto Labs

- Stratasys Ltd

If You Have Any Questions About This Report, Please Reach Out to Us @ https://market.us/report/medical-3d-printing-market/#inquiry

Drivers

Technological Advancements: Continuous improvements in 3D printing technologies boost the development of complex medical devices and implants.

Customization and Personalization: 3D printing allows for patient-specific implants and prosthetics, improving treatment outcomes and patient satisfaction.

Cost-Effective Solutions: Reducing manufacturing costs and material waste makes 3D printing an attractive option for medical applications.

Faster Production Times: Rapid prototyping and production capabilities enable quicker turnaround times for medical devices and implants.

Increased Funding and Investments: Growing investments from private and public sectors accelerate research and development in medical 3D printing technologies.

Rising Incidence of Chronic Diseases: The demand for customized solutions for chronic disease management drives the adoption of 3D printing in healthcare.

Regulatory Approvals: The approval of various 3D-printed medical devices by regulatory bodies boosts market confidence and adoption.

Trends

Integration with Advanced Technologies: Combining 3D printing with AI and robotics enhances precision and efficiency in medical device manufacturing.

Bioprinting Advancements: Progress in bioprinting technology is leading to the development of complex tissue and organ structures.

Regenerative Medicine: 3D printing is increasingly used in regenerative medicine to create scaffolds for tissue repair and organ regeneration.

Expansion of Material Options: The development of new materials, including bio-compatible and biodegradable options, is expanding 3D printing applications.

Personalized Medicine: Growing emphasis on personalized medicine is driving demand for customized medical solutions and implants.

Collaborations and Partnerships: Increased collaborations between technology providers, research institutions, and healthcare organizations are fostering innovation in 3D printing.

Educational Initiatives: Training programs and educational initiatives are raising awareness and expertise in medical 3D printing technologies.

Opportunities

Emerging Markets: Expanding healthcare infrastructure in emerging markets presents growth opportunities for medical 3D printing adoption.

Development of New Applications: Exploring new applications, such as 3D-printed pharmaceuticals and complex tissue structures, offers significant growth potential.

Improved Healthcare Accessibility: 3D printing can enhance healthcare accessibility by providing cost-effective and readily available medical solutions.

Regenerative Tissue Engineering: Advancements in regenerative tissue engineering create opportunities for developing innovative treatment options.

Customized Orthopedic Solutions: The demand for personalized orthopedic implants and prosthetics opens up new market avenues for 3D printing.

Innovative Prosthetics: The development of advanced, lightweight, and customizable prosthetic limbs provides growth opportunities in the market.

Partnerships with Medical Institutions: Strategic partnerships with hospitals and research institutions can drive market growth and innovation.

Restraints

High Initial Costs: The high cost of 3D printing equipment and materials can be a barrier for some healthcare providers and institutions.

Regulatory Challenges: Navigating complex regulatory requirements for 3D-printed medical devices can delay market entry and adoption.

Material Limitations: The limited availability of suitable materials for certain medical applications can restrict the growth of 3D printing in healthcare.

Technical Complexity: The complexity of 3D printing technology requires specialized knowledge and expertise, which may limit adoption.

Data Security Concerns: Ensuring the security of patient data and intellectual property in 3D printing applications poses challenges.

Limited Reimbursement Policies: Inadequate reimbursement policies for 3D-printed medical devices can hinder market growth and adoption.

Quality Control Issues: Ensuring consistent quality and reliability of 3D-printed medical products remains a significant challenge.

Contact Us :

420 Lexington Avenue, Suite 300 New York City, NY 10170,

United States

Phone:+1 718 618 4351 (International),+91 78878 22626 (Asia)

Email: [email protected]