3D printing has evolved into a versatile technology with a plethora of 3D printer filament materials, each offering unique advantages. Snapmaker, a leading player in the 3D printing industry, provides a diverse range of filaments that significantly contribute to printing efficiency. Let's delve into filament material exploration, understanding how materials like PLA, ABS, PETG, and others enhance the 3D printing experience.

- 1. PLA (Polylactic Acid): The Eco-Friendly Workhorse

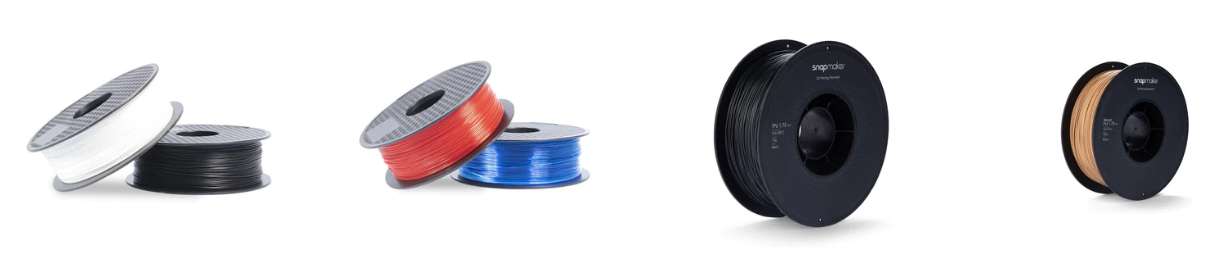

PLA stands out for its biodegradability, derived from renewable resources like cornstarch or sugarcane. Its low printing temperature and minimal warping make it an ideal choice for beginners. PLA's efficiency lies in its versatility, offering satisfactory results across a spectrum of applications, from prototyping to artistic endeavors. Snapmaker's PLA filaments, available in various colors, empower users with reliable and environmentally friendly printing.

- 2. ABS (Acrylonitrile Butadiene Styrene): Durability and Heat Resistance

ABS is renowned for its robustness and heat resistance, making it suitable for functional prototypes and end-use parts. Snapmaker's ABS filaments provide a balance between strength and flexibility, ensuring that printed objects withstand mechanical stress. Its capacity to endure higher temperatures expands the scope of applications, making it apt for components exposed to heat or demanding mechanical conditions.

- 3. PETG (Polyethylene Terephthalate Glycol): The Robust Performer

PETG combines the best of PLA and ABS, offering strength, impact resistance, and ease of printing. Snapmaker's PETG filaments maintain these characteristics while providing transparency and chemical resistance. This filament's efficiency shines in applications requiring durability, such as mechanical components or transparent prints where PLA might fall short.

- Specialized Filaments for Specialized Applications

Snapmaker goes beyond the basics, offering specialized filaments to cater to specific needs. For instance, flexible 3D filament printers like TPU (Thermoplastic Polyurethane) are perfect for printing flexible parts like phone cases or shoe insoles. Wood-filled filaments introduce a natural aesthetic, enhancing the appeal of prints. By providing a range of specialized filaments, Snapmaker empowers users to optimize printing efficiency for diverse projects.

- 5. Nylon: Strength and Versatility

Nylon filaments add another dimension to Snapmaker's material offerings. Recognized for their strength, flexibility, and chemical resistance, nylon filaments are suitable for applications demanding high performance. Snapmaker's nylon filaments open avenues for creating functional prototypes and end-use parts that require a combination of strength and flexibility.

Conclusion

In conclusion, Snapmaker's 3D printer filament material exploration provides users with a rich tapestry of options, allowing them to choose the right material for their specific project requirements. Whether it's the eco-friendly PLA, durable ABS, versatile PETG, or specialized filaments for unique applications, Snapmaker's range caters to the diverse needs of the 3D printing community. By understanding the characteristics and strengths of each filament, users can harness the full potential of Snapmaker 3D printers, ensuring efficiency and precision in their printing endeavors.