The Snapmaker 2.0 is an impressive 3-in-1 3D printer, seamlessly integrating 3D printing, laser engraving and cutting, and CNC carving in a modular design. Its all-metal construction ensures durability and precision.

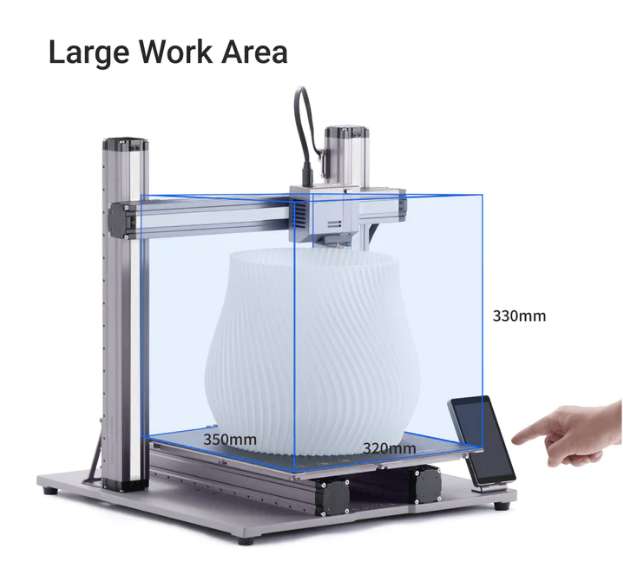

With a large work area (350mm x 350mm x 350mm), the machine supports a variety of materials for 3D printing, including PLA, PETG, Wood PLA, TPU, and ABS. The Quick Swap Kit facilitates easy transitions between 3D printing, laser, and CNC modules.

The Snapmaker 2.0 evolving modular system accommodates various tool heads and add-ons. Compatible with modules like Dual Extrusion 3D Printing, Rotary, and different Laser Modules (10W, 20W, 40W), it caters to diverse creative needs.

Its user-friendly Snapmaker Luban software simplifies configuration workflows for 3D printing, laser, and CNC machining. The 5" touchscreen provides an intuitive interface for efficient project management.

The machine excels in high print quality, filament runout recovery, auto leveling, and a flexible print sheet for 3D printing. Laser engraving benefits from a 0.2mm × 0.3mm laser spot, a built-in camera, and optional high-power upgrades (10W, 20W, and 40W).

For CNC carving, features like the ER11 collet, custom MDF platform, and dust resistance contribute to stable and precise machining. The 4-axis CNC machining capability with the Rotary Module expands its capabilities.

Available in two versions (A350T and A250T), the Snapmaker 2.0 is a versatile and user-friendly solution for makers, offering a seamless integration of 3D printing, laser engraving, and CNC carving.

Unveiling Key 3D Models Redefining the Snapmaker Experience

In the evolving realm of printing fans of Snapmaker have put together a carefully curated collection of remarkable 3D Printer models. These models are meticulously crafted to enhance the capabilities of their Snapmaker machines. The dedication and passion of this thriving community can be seen in the design and practicality of these creations. Now let's take a look, at some examples, from the Snapmaker community.

HMDuct2 for Snapmaker J1 (using 5015Fan): This model optimizes cooling for Snapmaker J1, employing a specialized duct design and a 5015 fan for enhanced efficiency during printing.

- Snapmaker 2.0 Side Mount Part Cooler: Focused on improving print quality, this side-mounted cooler directs airflow strategically for superior results in Snapmaker 2.0 projects.

- Snapmaker Fan Diverter with Support: Addressing overall performance, this model channels fan airflow precisely, displaying the community's commitment to refining machine dynamics.

- Snapmaker 2.0 Cable Strain Relief(s): Tackling cable management, this model provides solutions for strain relief, ensuring a neat workspace and prolonged component life.

- Free Laser Bed Clip for Snapmaker 2.0: Enhancing precision in laser engraving, this 3D-printed clip secures materials during projects on Snapmaker 2.0.

- Improved Part Cooling for Snapmaker 2.0: Focused on 3D printing, this model introduces an upgraded cooling system, emphasizing enhanced print quality and mitigating overheating risks.

These models epitomize the collaborative spirit of the Snapmaker community, offering practical solutions for enhanced functionality and customization. Whether it is optimizing airflow, managing cables, or improving cooling, each model contributes to refining the 3D printing experience on Snapmaker devices. Users can seamlessly integrate these 3D-printable designs into their workflows, displaying the power of collective innovation within the world of 3D printing.

Visit here: https://www.youtube.com/watch?v=LIsCNcBA5Ykt=226s